We use cookies to make your experience better. To comply with the new e-Privacy directive, we need to ask for your consent to set the cookies. Learn more.

HOW TO Use the fence packing rods for planing and straightening

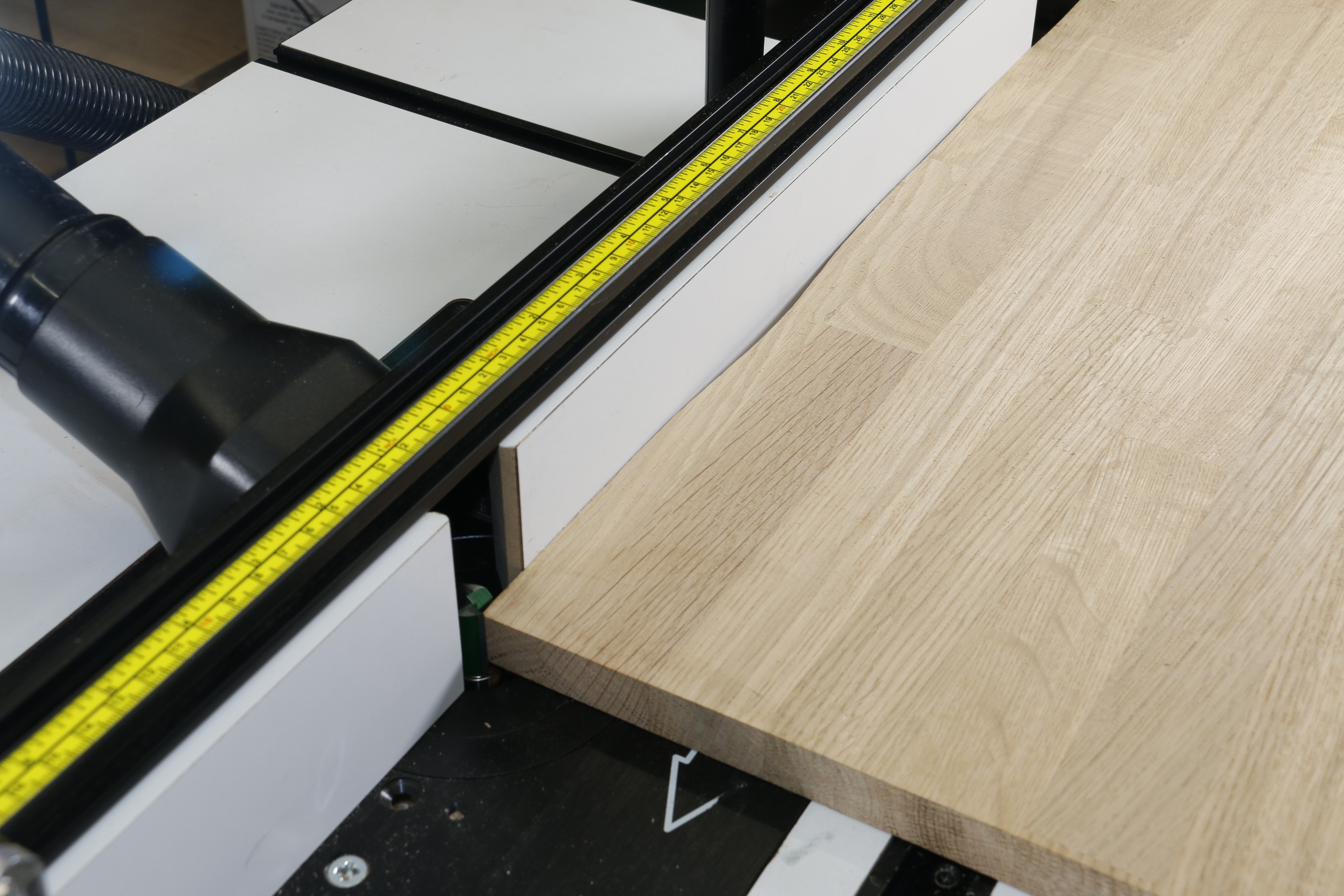

The Trend WRT and CRT Router Tables have a simple but effective function to allow edges of boards to be jointed or straightened using a straight cutter.

Working much the same way as a planing machine, the fences are staggered to offset them to support the work as it passes the cutter.

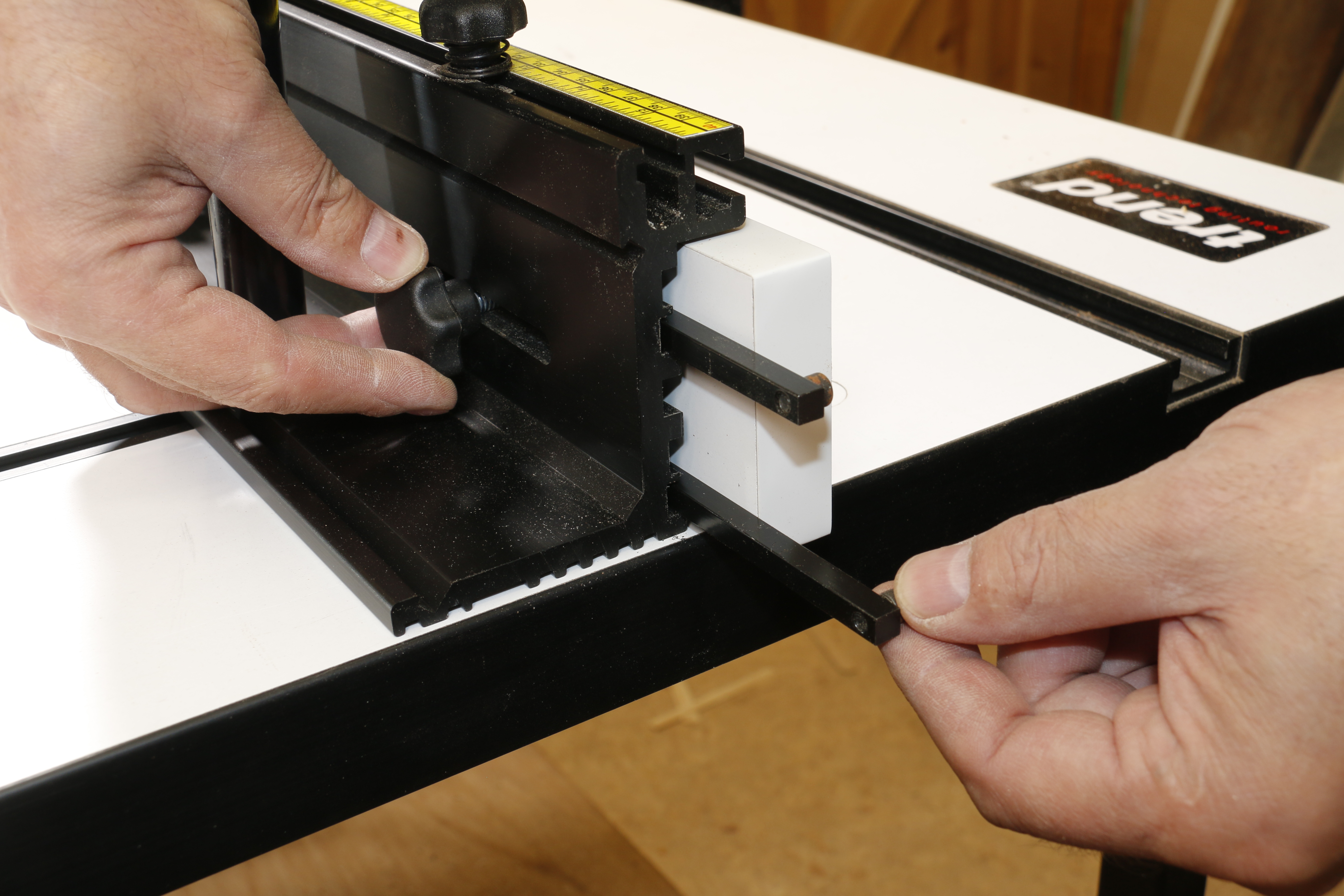

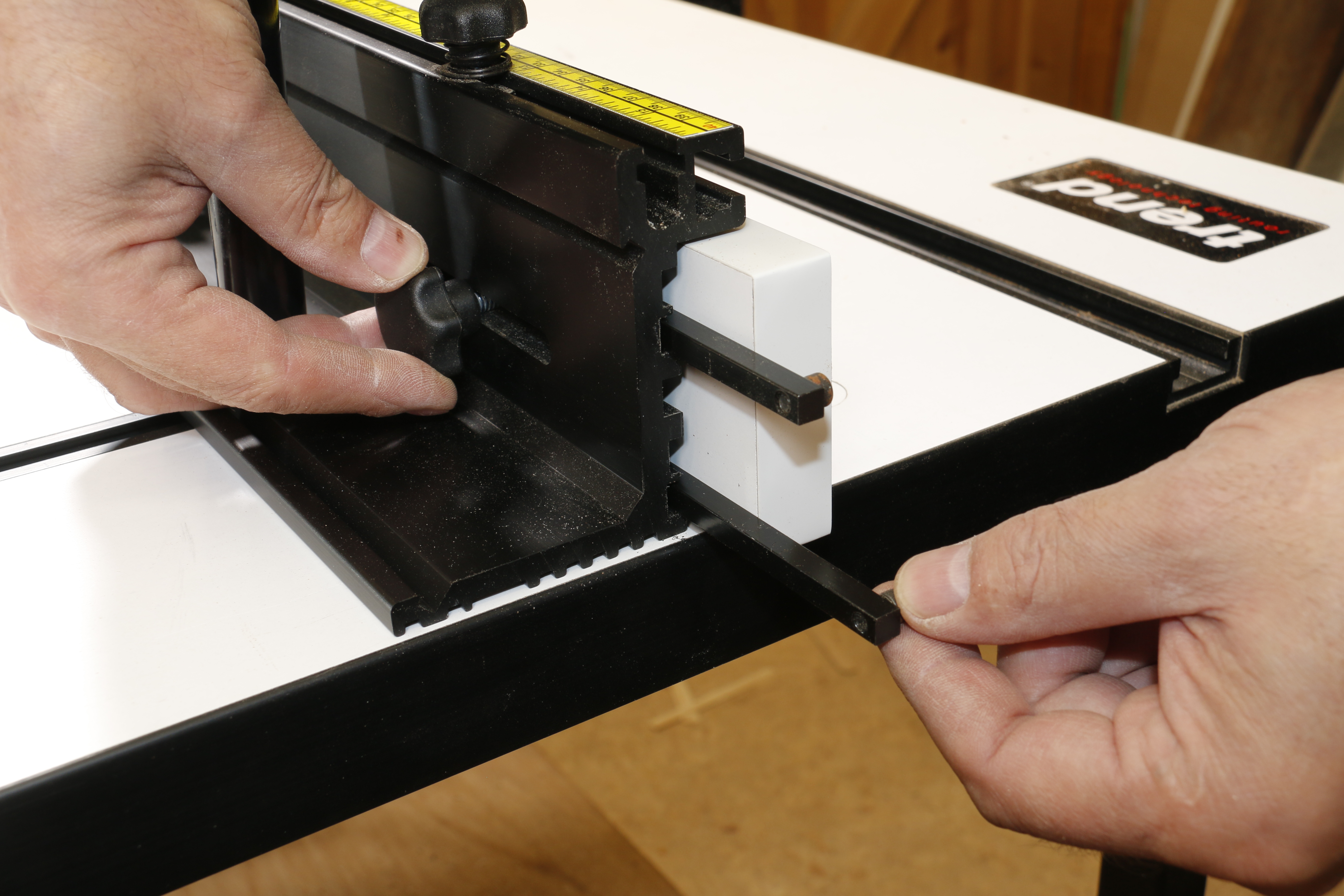

Both tables have small packing rods that store within the top of the fence when not in use. Slots in the outfeed fence extrusion allow the rods to slide in behind the outfeed fence facing to move it forwards by either 1.4mm or 2.4mm.

Slots in the outfeed fence extrusion allow the rods to slide in behind the outfeed fence facing to move it forwards by either 1.4mm or 2.4mm. Sliding them into position offsets the fence by the desired amount.

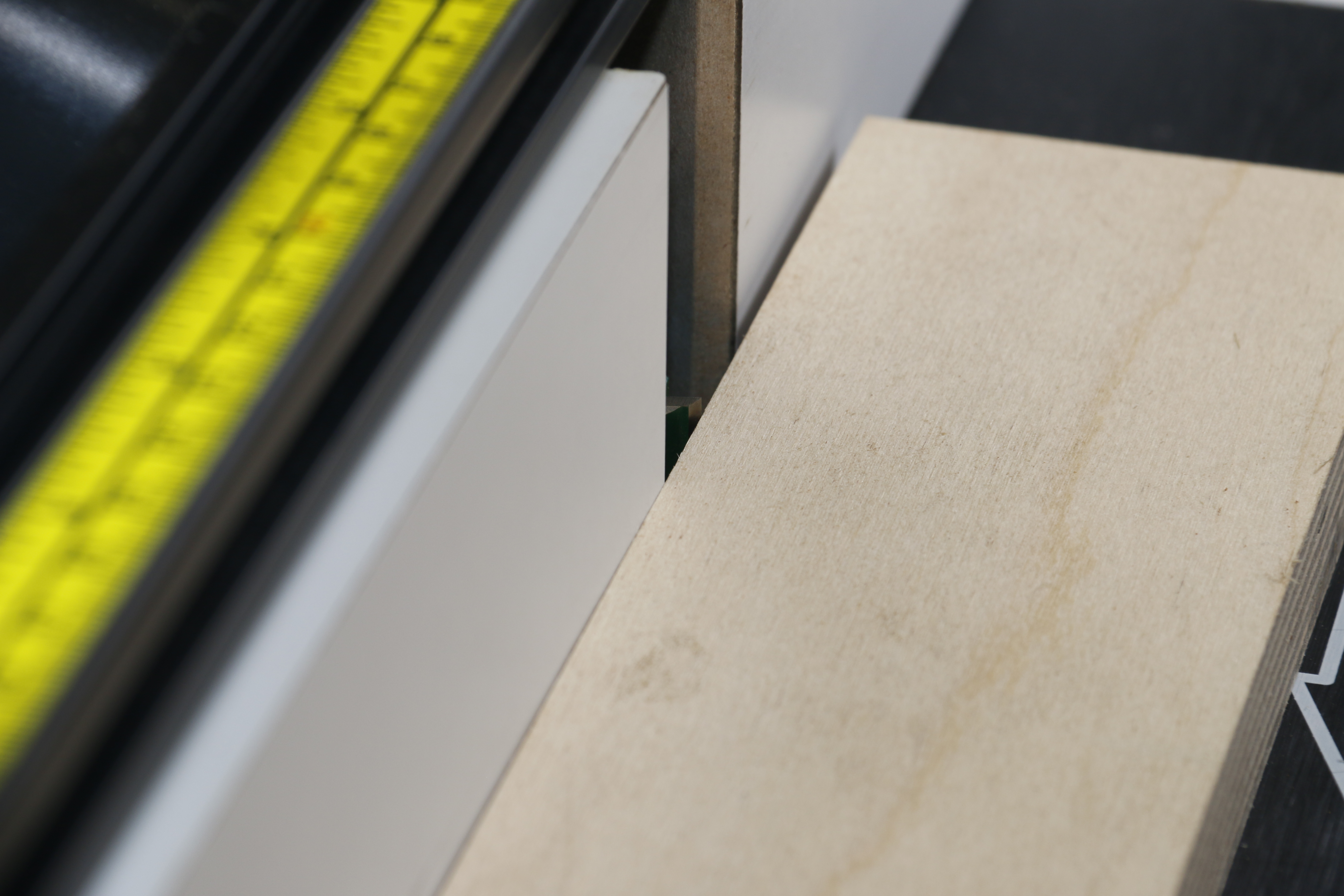

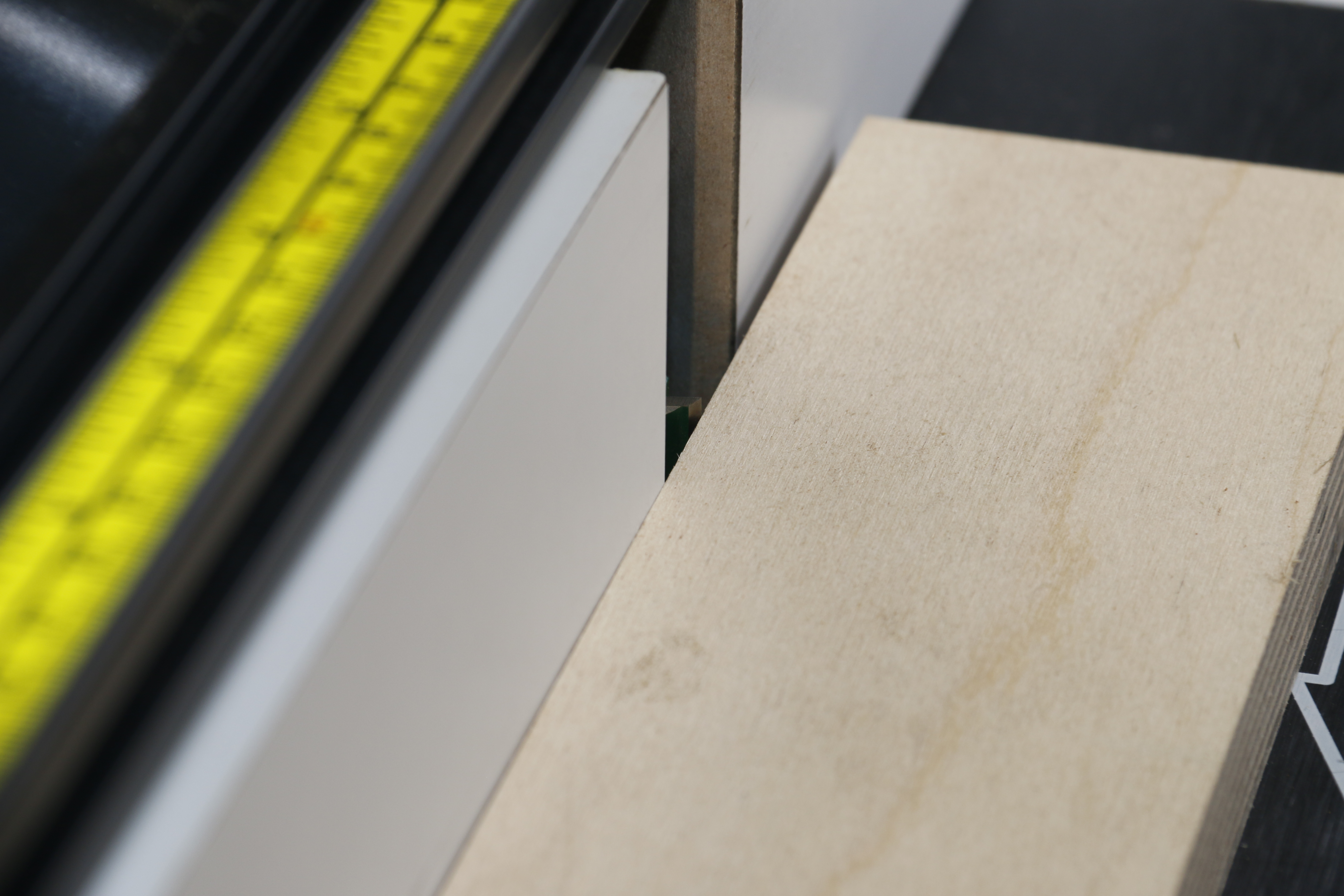

With the fence rods positioned for the required offset, a straight edge is placed against the outfeed fence facing and the fence adjusted until it is aligned with the edge of the cutter at its widest arc of cut.

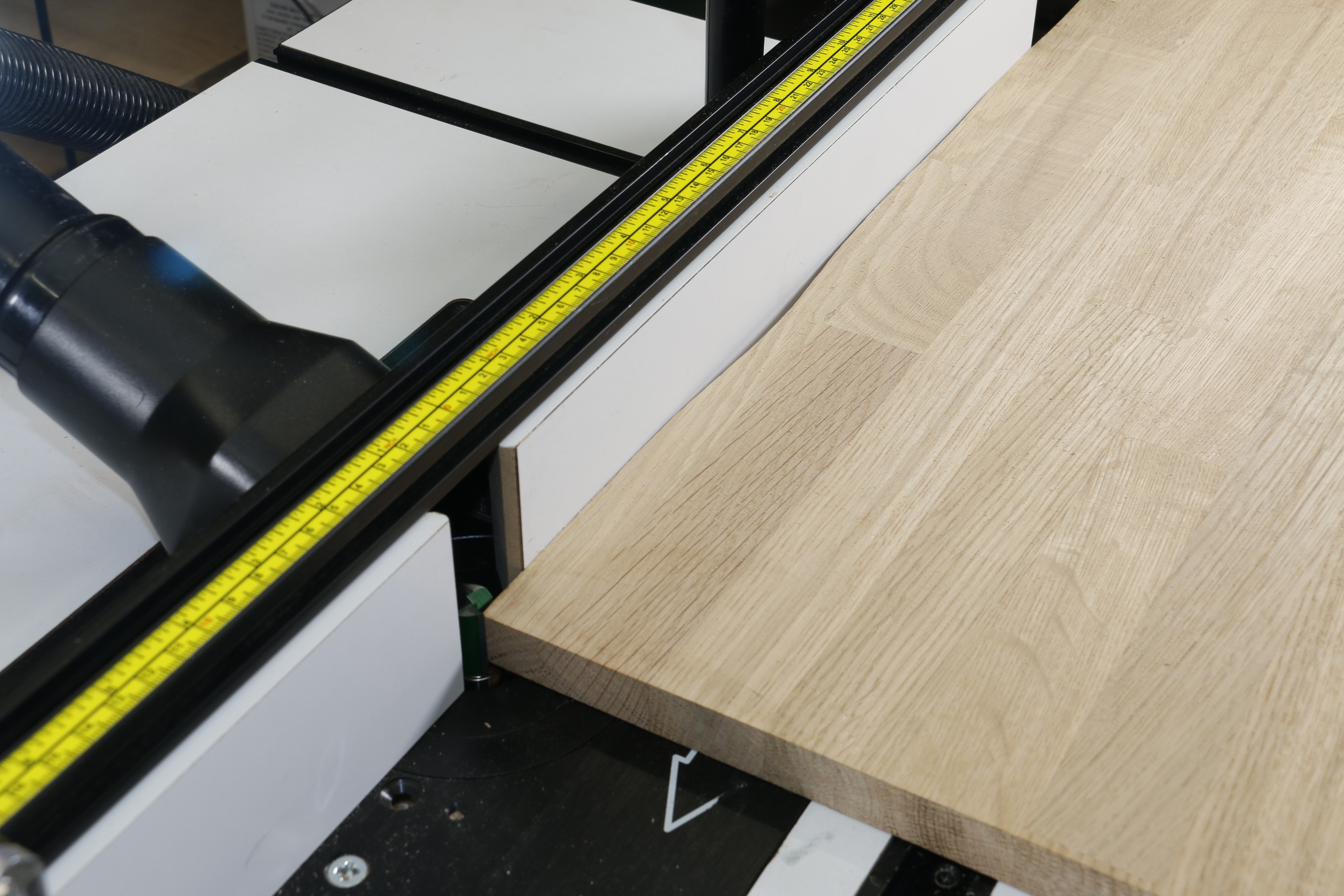

The offset can be checked by placing a straight edge across the fence facings to show the amount that will be removed per pass.

Placing the straight edge against the infeed, the cutter should engage the work by the same amount.

Any discrepancies on the edge of the workpiece, as seen against the infeed fence, will be removed as the work progresses. Any deeper hollows may need more than one pass.

Working in the same way as a machine planer is operated, the work is fed by keeping pressure against the infeed fence until it has started to engage the outfeed fence. Pressure is then applied to the outfeed to allow the cutter to remove the discrepancies on the infeed without deflecting the cut to ensure a straight edge.